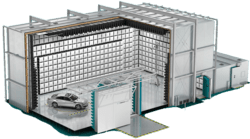

ETS Lindgren GTEM (5407) with manual manipulator offers manufacturers a compact and efficient method to undertake in-house radiated emissions and radiated immunity pre-compliance testing.

GTEM measurements correlate well to those made in an anechoic chamber or an open area test site (OATS).

The 5407 supports a recommended maximum EUT size of 50cm x 56cm x 90cm (emissions)

Included equipment:

Radiated Emissions:

- ETS Lindgren 5407 GTEM

- Manual boss manipulator

Radiated Immunity:

- Amplifier Research 30W1000M7 Broadband RF power amplifier

- 25 MHz to 1 GHz

- 30W

- Enables generation of electric field strengths exceeding 50 V/m

The GTEM is available to ship and install on short notice.

Contact equipment@emcfastpass.com for a quote.

From the manufacturer:

ETS-Lindgren’s Model 5407 GTEM!Test Cell enables users to perform radiated emissions and radiated immunity tests in less time than either an OATS or a chamber. Tests can be performed quickly and accurately throughout the product life cycle. Beginning with design qualification testing, and moving through to pre-compliance testing, full-compliance testing and production sampling, the model 5407 is a time saving device for your test lab. A typical radiated emissions test (10,000 point scan) can be completed in 15 minutes or less, while a typical radiated immunity test can usually be completed in half the normal time.

The GTEM! Test Cell is based on experience, not experimentation. Originally developed in the EMC Baden (Switzerland) Labs of ABB, the cell has been accepted in the EMC community for more than 10 years and is field proven daily at more than 400 installations worldwide. Measurements made with a GTEM! Test Cell are accepted for final compliance demonstration by the FCC for Part 15 & 18 radiated emissions testing, and comply with IEC 61000-4-3 Annex D for immunity testing. The GTEM!’s unique tapered shape, offset septum, resistive termination network, and absorber-lined back wall remove performance limitations of TEM cells and boxy enclosures. Electromagnetic wave and RF current termination are smooth and controlled. Field uniformity is +/- 3 dB up to 1 GHz, and +/-4 dB above 1 GHz.

- For all Phases of EMC Testing

- Design Qualification

- Pre-Compliance

- Full Compliance IEC 61000-4-3 ANSI C63.4

Door Dimension Primary (W): 686 mm (27.01 in)

Door Dimension Secondary (H): 385 mm (15.16 in)

Door Dimension Secondary (W): 460 mm (18.11 in)

Highest Accuracy Transverse Test Surface in Center of Cell (H)5: 250 mm (9.84 in)

Highest Accuracy Transverse Test Surface in Center of Cell (W)5: 350.0 mm (13.78 in)

Maximum Recommended Transverse Test Surface in Center of Cell (H)6: 500.0 mm (19.69 in)

Maximum Recommended Transverse Test Surface in Center of Cell (W)6: 560 mm (22.05 in)

Maximum Septum Height7: 897 mm (35.32 in)

Outer Cell w/Base Dimension(H)8: 2.1 m (6.89 ft)

Outer Cell w/Base Dimension(L): 4.0 m (13.12 ft)

Outer Cell w/Base Dimension(W): 2.2 m (7.22 ft)

6From quasi-static E-Field with H=2/3 Septum Height and W=2/3 Septum Width

7Measurement Taken at Rear of Test Volume